How to install a molded case circuit breaker?

The article takes the installation wiring method in the external accessories of the molded case circuit breaker as an example to analyze the three installation methods of fixed installation, plug-in installation and withdrawable installation of the molded case circuit breaker. The focus is on the withdrawable installation method in detail. Instructions, for users to choose a suitable way to provide help in different situations.

1. Fixed installation

The fixed installation method is the most commonly used method among plastic case circuit breakers, and it is also the simplest method. The circuit breaker body is directly fixed on the mounting plate in the distribution cabinet or the mounting bracket with the random screw. The matching terminal or busbar is directly connected to the incoming and outgoing wiring screw of the circuit breaker body. The fixed installation method can also be equipped with an external expansion row connection according to the requirements of the application site. It is divided into two ways: the front wiring and the rear wiring. The supporting wiring structure is generally an expansion type. If necessary, you can specify it when ordering. The manufacturer will distribute it with the product. When the user needs to repair or replace the circuit breaker, the upper-level circuit breaker must be disconnected first, and then the cable or wiring block can be removed from the fixed screw of the circuit breaker before the circuit breaker can be repaired or replaced. The fixed installation method has some advantages when replacing the circuit breaker. Trouble, but the price is relatively affordable.

2. Plug-in installation method

Plug-in installation method is composed of two parts: plug-in installation base and movable body, similar to socket and plug structure. The base is fixed on the crossbeam of the power distribution cabinet by screws, and the incoming and outgoing cables (bus bars) are directly connected to the fixed base. There is a contact device for plugging and unplugging the conductive rod on the in and out contact of the base. The contact device is generally composed of a conductive rod, a contact piece, a spring, a support, etc. The conductive rods in the contact are evenly arranged around the Positioning groove, the contact piece is evenly wrapped in the positioning groove, the contact piece needs to be stably and reliably fixed on the conductive rod, the middle of the contact piece is provided with a positioning hole, the outer edge of the support piece is provided with multiple supporting feet, and the supporting feet are clamped in In the positioning hole, the contact piece of the outer ring is wrapped around the conductive rod in a circular shape, and the upper and lower ends of the contact piece are wrapped with springs. The other part of the matching plug-in conductive column can be fixed on the back of the circuit breaker with a screw. When you need to insert it, align the conductive post on the back of the movable body with the jack on the base and push it in. In order to ensure that the breaker will not be loosened due to the normal opening and closing of the circuit breaker after insertion, the screw can be fixed through the circuit breaker mounting hole On the base. When the circuit breaker needs to be overhauled or replaced, the circuit breaker only needs to be in the open state, and the movable body can be pulled out directly from the fixed base after loosening the fixed screw. This insertion and removal process generally does not require the use of special special tools, nor does it need to disassemble the incoming and outgoing cables or busbars. Because the plug-in type circuit breaker is directly plugged and unplugged, it is more laborious. The rated current in general application is not too large. Special attention should be paid when using it. The reliability of the contact will directly affect the normal use of the circuit breaker. Therefore, it is necessary to check whether the contacts are pressed tightly and whether the contact is reliable during installation, so as to reduce the contact resistance and improve product reliability. Compared with the fixed installation method, the plug-in installation method of the small current specification molded case circuit breaker can indeed bring convenience to the user when it is replaced and repaired.

3. Withdrawable installation method

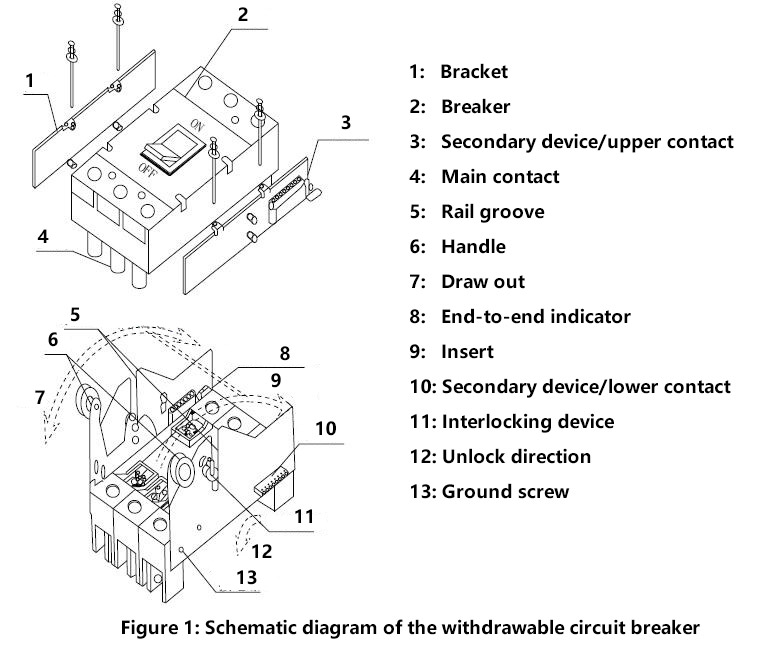

Withdrawable circuit breaker structure diagram shown in Figure 1.

Withdrawable device is similar in principle to plug-in device, and it is also composed of two parts: fixed installation base and withdrawable circuit breaker body. However, the structure of the withdrawable device is much more complicated than that of the plug-in device. Because of the lever principle, the current specification of the withdrawable circuit breaker can be larger, and the operator can complete the replacement operation of replacing the large current circuit breaker with a small amount of force. , Which greatly reduces the labor intensity caused by repair or replacement of circuit breakers. The back of the circuit breaker body is the same as the plug-in type. First, fix the conductive main contacts in the accessory bag on the back of the circuit breaker with screws. The left and right sides of the circuit breaker need to be installed with transmission brackets. The following describes the working method and application of the withdrawable installation method. Description.