Shanghai Liangxin Electrical Co., Ltd. (Nader) Solemn Statem

The Company has been receiving feedback on the false information about the flame resistance of the miniature circuit breakers produced by our company spread by ill-intentioned competitors, which, so far, has caused extremely adverse impacts on the brand image of our company. We hereby make a solemn statement that the miniature circuit breakers produced by Nader are in full compliance with the national flammability standard for such products and RoHS requirements, and have passed CCCCETUV verification and validation. Nader is also one of the "green" electrical products manufacturers in the domestic low-voltage electrical equipment industry. We welcome and accept supervision from end users.

All the malicious spreading of the information on Nader‘s miniature circuit breakers of not being inflaming retarding is suspected of defaming that is subject to legal actions. Such malicious spreading and dissemination of false information and videos against our products is vicious competition. We hereby solemnly request the perpetrator to stop spreading such false information. Otherwise, we will reserve the right to take any legal actions.

We hereby provide the technical interpretation of fire retardancy test:

1. It is unscientific and unreasonable to directly igniting the guide rail snap spring of Nader's miniature circuit breakers with lighter to evaluate the excess heat resistance and flame resistance of the product, and it does not meet the standard test requirements.

2. The national standard GB10963.1-2005 "Electrical Accessories: Overcurrent Protection Circuit Breaker for Household and Similar Use ,Part I: AC Circuit Breaker" has clearly set forth the technical requirements for excess heat resistance and flame resistance in Chapter 8.11, with the following provisions:

8.11 Excess Heat Resistance and Flame Resistance

If the adjacent current-carrying parts reach a very high temperature in the event of a fault or overload, the external parts made of insulation materials of the circuit breaker should not burn readily and spread the flame.

Check whether the product is qualified through visual inspection and test specified in Chapter 9.15.

Carry out test in accordance with Excess Heat Resistance and Flame Resistance (Glow-wire Test) set forth in Chapter 9.15 to determine the conformity. The provisions are as follows:

9.15 Excess Heat Resistance and Flame Resistance (Glow-wire Test)

Carry out Glow-wire Test according to Chapter 4 to Chapter 10 in GB/T 5169.10-1997 under the following conditions:

- Conduct tests of the insulated external parts that are necessary to keep the current-carrying parts and protective circuit components of a circuit breaker in position at the temperature of (960±15) °C;

- Conduct tests of all other insulated external parts at a temperature of (650±10) °C.

Note 1: The Glow-wire Test is to ensure that the electrically heated test wire does not cause ignition of the insulated parts under specified conditions or to ensure that the insulation materials which may be ignited by the heating test wire under specified conditions would burn for a limited period of time without causing a fire spreading by the flame or burning parts or particles falling from the test parts.

Note 2: For the purposes of this test, consider the base of the surface mounted circuit breaker as an external part.

Note 3: The ceramic parts will not be tested.

Note 4: If several insulated parts are made of the same material, only one of the sample parts shall be tested at the corresponding glow-wire test temperature.

This test is carried out on one test sample.

In case of doubt, repeat the test with two other samples.

Apply glow-wire once during test.

The test sample shall be placed at its most unfavorable position against its intended use (the surface is in a vertical position).

The top of the glow-wire shall be applied to the specified surface of the test sample, taking into account the intended conditions of use of the heating element or the glowing element which may be in contact with the test sample.

The test sample is deemed to pass the Glow-wire Test if the following requirements are met:

- There is no visible flame or continued glow;

- The flame and glow on the test sample are extinguished within 30 seconds after the glow-wire is removed.

Besides, it should not set the tissue on fire or burn the pine board.

The miniature circuit breakers produced by our company have been validated by CCC type test in strict accordance with GB 10963.1-2005 and obtained a qualified 3C test report and certificate.

The above national standard provisions clearly stipulate the flame retardant requirements and test method on the miniature circuit breakers:

1. Conduct tests of the insulated external parts that are necessary to keep the current-carrying parts and protective circuit components of a circuit breaker in position at the temperature of (960±15) °C;

2. Conduct tests of all other insulated external parts at a temperature of (650±10) °C;

Carry out Glow-wire Test according to Chapter 4 to Chapter 10 in GB/T 5169.10-1997.

The miniature circuit breakers produced by our company have been validated through CCC type test carried out by TILVA of Shanghai Electrical Apparatus Research Institute (SEARI) in strict accordance with GB 10963.1-2005. See the 3C Test Report below:

Our IQC Department carries out monthly glow-wire test of the plastic insulation parts of our products in strict accordance with national standards. The test results are as follows:

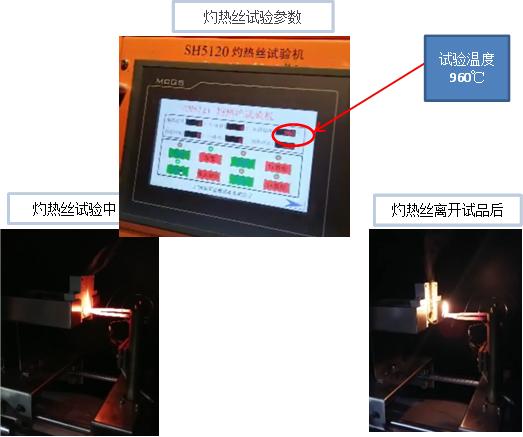

1. Body Case Test

Based on the product structure of our company, fix the conductive current-carrying parts of the product body case to its position and use glow-wire to ignite the body case for 30 seconds at a temperature of (960±15) °C, the flame on the surface of the test sample must be extinguished in 30 seconds after the glow-wire is removed. During the actual test, the flame on the shell goes out in 2-6 seconds, suggesting that our products meet the standard requirements. The test results are as follows:

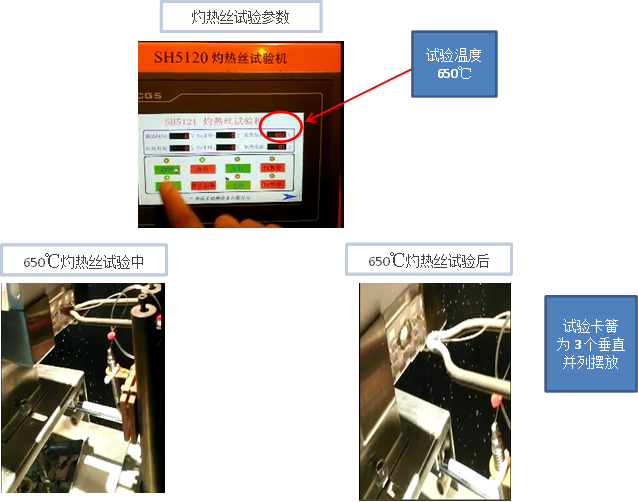

2. Test of Other Components not in Contact with Conductive Current-carrying Parts

Test the other external insulated parts not in contact with conductive current-carrying parts, such as the snap spring used to mount and fix the circuit breaker. Use glow-wire to ignite the snap spring for 30 seconds at a temperature of (650±10) °C, there shall be no flame or dripping on the surface of the snap spring. The test results show that our products are in line with the standard requirements (see below figure):

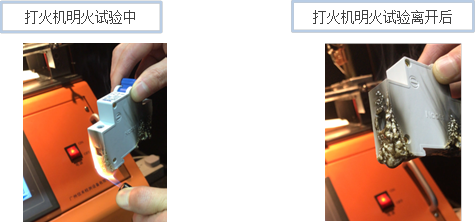

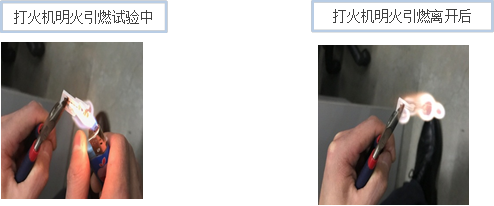

We test the product using customer's test method with a lighter:

1. Light the corner of the shell with a lighter for 30 seconds, the flame on the shell goes out after 12-18 seconds. See below:

Light the corner of the snap spring parts with a lighter for 30 seconds, the snap spring continues to burn after removing the fire source and is burned up after 1 minute 30 seconds. Then the shell is self-extinguished. See below:

The flame retardancy of the snap spring is validated during the Glow-wire Test. However, the snap spring continues to burn when ignited with a lighter, mistakenly suggesting that the products are defective. The reason lies in the lighter gas - butane - whose outer flame temperature reaches up to 700-800°C when burning, exceeding the heat-resistant rating of the materials capable of glow-wire flame resistance up to 650°C.

We have referred this to experts from SEARI, who replied that insulating plastics used in miniature circuit breakers must withstand the excess heat arising from overload and short circuit of current-carrying parts. But the heat is coming from heat conduction rather than open flames. The heat resistant efficiency shall be validated according to the heat-resisting rating and quality coefficient (such as at 960°C or 650°C) with fire controlled within the product. The test method of using lighter to directly ignite the non-current-carrying parts with heat resistance up to 650°C is temporarily incapable of effective judgment. It is suggested to conduct the test verification in strict accordance with the provisions set forth in Chapter 9.15 of the current GB10963.1-2005.

In summary, flame retardancy test of miniature circuit breakers shall be carried out in strict accordance with the excess heat resistance and flame resistance test requirements set forth in Chapter 9.15 of the international standard GB 10963.1-2005. The test method of using a lighter to ignite the miniature circuit breakers is a misleading approach to test flame retardancy of the product.

Using a lighter to directly ignite the snap spring parts with the purpose of maliciously exaggerating the flame retardancy defect of our products constitutes unfair competition. We will reserve the right to take legal actions against such malicious competition and talebearers of false information.

Shanghai Liangxin Electrical Co., Ltd. (Nader)

March 28, 2017