How are circuit breakers made - Nader's assembly line

By:Nader Updated:August 06,2021 19:14PM

Do you know what manufacturing processes are required for a circuit breaker at factory? The production of circuit breakers includes six major working procedures: welding, assembly, inspection, electronics, OTS, and tooling. Today we are going to learn about the assembly technology of products in Nader manufacturing line.

Nader is a company focusing on the high-end market of low-voltage electrical appliances. With the brand positioning of high-end low-voltage electrical system solution experts, Nader is committed to people's more safe, convenient and efficient use of electric energy. Since its establishment in 1999, Nader has established a rich product line from the original miniature circuit breaker to now, covering the whole series of low-voltage electrical appliances. It provides low-voltage power distribution solutions for Huawei, Vanke, State Grid, Vertiv, Mitsubishi, Hitachi and other enterprises, and serves large-scale landmark projects such as Xitieshan photovoltaic power station, Qinghai Tibet railway project, bird's Nest National Stadium, Hong Kong-Zhuhai-Macao Bridge, Dubai International Airport, etc.

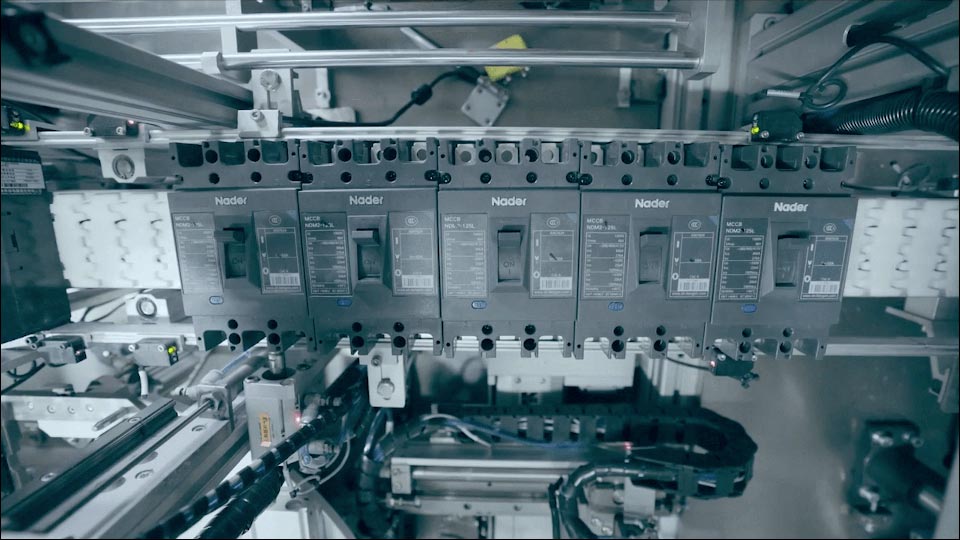

Automated Production Line

Automated production line is the key for Nader to achieve lean production and improve product quality in the manufacturing process. Nader currently has a total of 48 automatic production lines of various types, which can automatically produce miniature circuit breaker, molded case circuit breaker, air circuit breaker, automatic transfer switching equipment, isolating switch, contactor and other products, which can meet the needs of different customers and different industries.NDC1/C5K intelligent assembly line

NDC1/C5K intelligent assembly line is the common line for NDC1 and NDC5K products. It covers the whole series of production with specifications from 115A to 2650A. NDC5K vacuum bubble assembly process is the core process of the line. Before assembly, special equipment is needed to check the vacuum degree to ensure the reliability of the product. At the same time, the production line realizes automatic detection and recording of key data, such as early failure, contact parameters, pressure resistance, machine performance, etc., which ensures the continuity of product quality.NDW2 Assembly Line

The NDW2 assembly line has advanced test procedures. The mechanical running-in 8 stations meets the number of tests for each product 50 times, and it has high current and voltage characteristics test, comprehensive test, loop resistance and synchronization test, withstand voltage power frequency test and other testing equipment, Satisfy product performance from the root cause and ensure product quality.NDM2/3-125 digital production line

NDM2/3-125 digital production line applies the core concept of the integration of lean manufacturing, automation and informatization, introduces automatic assembly equipment and low-cost automatic chemical equipment through lean production line design, cooperates with lean logistics distribution, realizes industrial interconnection of equipment with the help of electrical technology and digital technology, runs through on-site informatization (such as the application of MES system), and improves quality and efficiency, The goal of intelligent manufacturing.NDB1/2 series automated assembly line

The automatic production line of NDB1/2 series products covers part of the product’s manual assembly and coding, pressure resistance, pad printing, circlip, buckle and other processes. It is a model production line for the full range of Nader terminal products with high production efficiency, the defective rate is extremely low, and the operation difficulty is small.Key Process

In the assembly process, Nader has a number of key process technologies, such as semi-finished product automatic assembly, automatic winding, laser marking, intelligent electric screw error prevention, automatic packaging, etc., through continuous exploration and innovation of the assembly process, more and more professional And intelligent.Semi-finished product automatic assembly and mechanism seat

For the key components of the product, through the introduction of high-precision and automated special equipment, fully automatic assembly is realized, replacing the quality risk caused by manual assembly, and improving the assembly consistency and production efficiency of key components.

Automatic winding process

After the NDC1-09/95 coil automatic winding machine starts, it will automatically transfer the skeleton to the winding area, and the winding machine will automatically process the coil connector. After winding according to the set parameters, the winding machine will automatically process the other end of the coil, and finally automatically cut the material. The whole winding process of the coil is completed by the equipment.

Laser marking technology

NDG3-32 automatic marking machine combines automatic manipulator with laser marking, and has networking function. The equipment is connected to SAP to read the work order information, and can generate the corresponding marking content according to different work order information for automatic laser marking, which not only greatly improves the production efficiency, but also meets the requirements of multi model mixed line production.

Intelligent electric batch

The intelligent electric batch can prevent the screw from being damaged in terms of torque and quantity, and fundamentally solve the problems of screw misfit, missing installation and not tightening. In the process, the auxiliary force arm of screw fastening is added to reduce the setback force of large torque screw in the operation process, eliminate the potential safety hazard, and make the post operation easy and convenient.Automatic packaging technology

Automatic packaging technology, from small boxes to packing, to achieve automatic production, packing speed up to 280 boxes/day. before and afterpacking, there is a scanning and identification system to bind products and boxes, which is convenient for digital inventory management.

Nader is a company focusing on the high-end market of low-voltage electrical appliances. With the brand positioning of high-end low-voltage electrical system solution experts, Nader is committed to people's more safe, convenient and efficient use of electric energy. Since its establishment in 1999, Nader has established a rich product line from the original miniature circuit breaker to now, covering the whole series of low-voltage electrical appliances. It provides low-voltage power distribution solutions for Huawei, Vanke, State Grid, Vertiv, Mitsubishi, Hitachi and other enterprises, and serves large-scale landmark projects such as Xitieshan photovoltaic power station, Qinghai Tibet railway project, bird's Nest National Stadium, Hong Kong-Zhuhai-Macao Bridge, Dubai International Airport, etc.