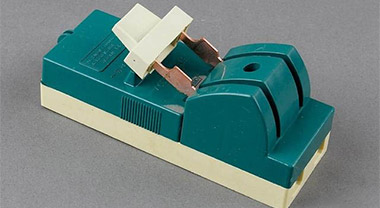

Analysis of MCB opening and closing coil burnt out

Circuit breaker is a kind of load switch, which has short-circuit and overload protection functions, and its short-circuit protection function is realized by electromagnetic coil. Because of its complete protection function, easy maintenance and use, it is widely used in power systems. This article introduces the reasons and preventive measures for the burning of circuit breaker opening and closing coils.

The reason for the burning of the opening coil

1. Mechanical failure of the opening electromagnet. Loose coil causes the electromagnet to move when the circuit breaker is opened, which causes the iron core to jam, causing the coil to burn; or because the iron core has a short movable stroke, when the opening circuit power is turned on, the iron core does not open the tripping mechanism to make the coil energize for a long time burn.

2. The circuit breaker refuses to open. When the control circuit is normal, the failure of the circuit breaker to fail to open is the link mechanism problem, such as improper adjustment of the apex, so that the strength of the breaker's opening iron core push rod cannot make the mechanism trip in time; or the protective locking mechanism does not act, resulting in The coil is overloaded, causing the opening coil to burn out.

3. Improper adjustment of the stroke of the auxiliary switch in the open state. When the circuit breaker is in the open state, the auxiliary switch should be adjusted to be within the stroke range of the open state. However, when adjusting parameters such as breaker distance and over-travel, the initial state of the circuit breaker opening is not adjusted accordingly, which will cause the auxiliary switch to fail to switch the opening circuit normally and cause the opening coil to burn out.

4. Improper use of auxiliary switch contacts of the opening control circuit. When the closing time of the circuit breaker is extremely short, much less than the opening time of the circuit breaker, the circuit breaker will be closed in place when it is tripped in the future. At this time, the delay function of the delay contact will be meaningless. On the contrary, during the opening process of the delay contact, due to the small insulation gap between the static and dynamic contacts of the auxiliary switch, the phenomenon of arcing often occurs, which will burn out the contacts of the auxiliary switch and then cause the opening coil to burn out.

5. The protection control device fails. The opening command is issued by the protection control device. If the opening relay in the device is faulty, or the auxiliary switch contact of the opening control circuit has a large operating stroke, causing the opening command to fail to exit in time, the opening coil will be long. Time is charged and burned.

6. The resistance of the opening circuit is too large. The insulation of the opening coil circuit is reduced, or the resistance of the control circuit is too small, which causes a large voltage drop in the opening control circuit, causing the voltage to fail to reach the value of the coil opening action, and the opening coil is burned out for a long time. .

Measures to prevent burning of the opening coil

1. Change the time-delay moving and closing contacts of the opening circuit to a pair of moving and closing contacts. Check the contacts of the auxiliary switch and the arm screws of the auxiliary switch frequently, and adjust the position of the auxiliary switch correctly to make the auxiliary switch open. The opening and closing positions of the device are correctly and effectively coordinated.

2. Fix the opening coil, and always check whether the core of the opening coil is jammed.

3. The opening command time issued by the protection control device must be able to make the opening coil work, but also be able to exit the opening command in a short time.

4. In the annual maintenance work, the connecting rod mechanism of the circuit breaker should be adjusted correctly, and the free tripping of the circuit breaker should be regularly checked whether it is normal and whether it can be reliable within 30% to 65% of the rated voltage during the low voltage operation test. Tripped.

The reason why the closing coil is burnt

1. Breaker mechanism failure. When the circuit breaker closing control circuit is normal, the internal conductive rods and transmission connecting rods of the circuit breaker body are jammed, or because the circuit breaker operating mechanism is not well connected, and the protective lock interlocking mechanism does not act, the vertex is adjusted to a deviation High, causing the circuit breaker to refuse to close, overload the closing iron core, and cause the closing coil to burn out.

2. The auxiliary switch stroke position is improper. During normal closing, the coil circuit of the closing contactor of the circuit breaker is connected in series with the moving-off delay contact of the auxiliary switch. After closing, the auxiliary switch contact automatically cuts off the closing circuit, the auxiliary contact cannot be opened or arced, the closing contactor is self-maintained through the reclosing circuit or the green light circuit, and the closing coil is burned out after being charged for a long time.

3. The protection control device fails. The closing command is issued by the protection control device. If the closing relay in the protection device fails, or the auxiliary switch contact of the closing control circuit has a long operating stroke, causing the closing command to fail to exit in time, the closing coil will be caused Burn out after being charged for a long time.

4. The closing contactor is faulty. When the circuit breaker is closed, because the closing current is relatively large, the control circuit cannot directly control the closing coil, and can only indirectly connect the closing coil through the closing contactor. Therefore, when the closing contactor fails, it cannot be opened in time , Make the closing coil energized for too long and burn the coil. In addition, the coil resistance of the closing contactor becomes larger, which will cause insufficient suction force when the closing contactor is normally energized, and the main contact will generate arcing, and the contact resistance of the main contact of the closing contactor will increase, which indirectly affects the circuit breaker The excitation current of the closing coil makes the excitation strength of the closing coil insufficient, the iron core cannot operate normally, and the closing coil is overloaded and burned.

5. The closing power supply capacity drops or the wire resistance of the closing control loop is too large, which causes the voltage across the closing coil to be lower than 80% of the rated voltage at the moment of closing and burns.

Measures to prevent the closing coil from burning

1. Strengthen the inspection and maintenance of the closing contactor. Every minor repair or periodic overhaul must check the contact area and contact pressure of the moving and static contact surfaces.

2. Adjust the position of the auxiliary switch.

3. The closing command time issued by the protection control device can be enough to make the closing coil work, and can exit the closing command within the specified time.

4. The attendant is required to remove the control circuit fuse and open the recloser switching circuit before permitting work to avoid burning of the closing coil during maintenance and testing.